- Turbocad mac designer 2d steel tube how to#

- Turbocad mac designer 2d steel tube full#

- Turbocad mac designer 2d steel tube software#

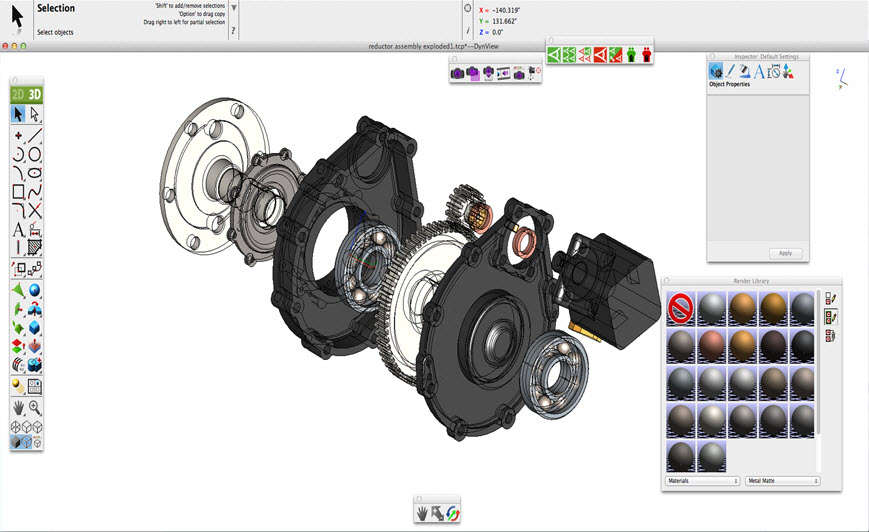

Later on, customers started sending CAD drawings making it even easier. Early on, I used to do all of my layouts mathematically but then CAD appeared and I realized the advantages. You will at that point have effectively subtracted the material stretch but done it visually. The line to the left represents the left side of the right side drawing. The line that is most right represents the right side of the chassis bottom. Then grab the right side drawing and snap it to the construction line. Snap a construction line to the lower right corner and then move it horizontally left the K factor distance. Picture you are looking at the inside of your chassis bottom and about to move the right side drawing as I described. You will end up with two lines a K factor apart. Desktop CAD solution for the PC & Mac which assist architects & engineers with 2D drafting, 3D modeling and photo realistic rendering. Snap the sides to the bottom drawing but overlap by the K factor.

Turbocad mac designer 2d steel tube software#

You don’t need another CAD software to do this. Hundreds of professional drafting and design tools, incredible file support, video and interactive tutorials, photorealistic rendering and drag-and-drop symbols provide everything you need to create presentation-ready home plans, technical drawings, mechanical designs, artistic. That is the amount of material you will gain. With TurboCAD ® Deluxe 2D/3D your options are unlimited. I didn’t understand the part about “taking half the stretch from each side of the bend” but just to keep it simple and, as Madman said, bend a piece of identical material, measure the length, bend it to 90 degrees, measure both sides and subtract them from the flat length. I owned a precision sheet metal shop for 30 years and that is the most foolproof way to get a precise number.

Turbocad mac designer 2d steel tube how to#

Madman’s description of the K factor is spot-on, especially how to figure out what the number is for a given material, thickness, and inside bend radius. Note that these are both builds in progress so they have stuff attached to the pan: Here are photos I pulled from Instagram to give you an idea. These chassis are very basic rectangular pan with simple mounting flanges on each end.

Turbocad mac designer 2d steel tube full#

I’ve bought a Crossfire, bought the full feature SheetCam software, but I’m still using the same CAD software. I’ve been using TurboCad Designer which has no sheet metal specific capabilities. I have no idea what they may have done in their software to handle the bend radius, K factor, etc. Is CAD software with sheet metal capability REALLY a requirement?įor years I’ve been designing my Nolatone tube amp chassis creating a simple 2D drawing of the flattened chassis with all the holes where I want them and sent a dwg or dxf to a sheet metal fab shop to cut and bend them. These are simple rectangular pans with mounting flanges on the end. I’m wanting to produce very small quantities of tube amp chassis pans out of. I have TurboCad Designer ($79 software that doesn’t have sheet metal design capability, you have to buy their $1500 Platinum version for that), a Crossfire, and a Baileigh finger brake.

0 kommentar(er)

0 kommentar(er)